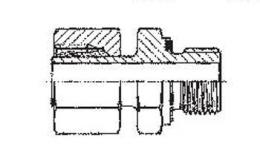

Type galvanized steel

Materials

Body: Galvanized steel or available elastomer seal: NBR

Temperature range:

-40 °C to max. +120 °C (with elastomer seal: -35 °C to max. +100 °C)

Stainless Steel Type & NC Coupling

Materials

Body: 1.4571, any available elastomer seal: FKM

Temperature range:

-60 °C to max. +400 °C (with elastomer seal: -20 °C up to max. +200 °C, NC couplings up to +550 °C on request)

Mounting Cutting Ring Couplings and NC Clamping Ring Couplings

1) Cut the pipe in a rectangular way and deburr and clean the inside and outside. Do not use a tube cutter. For thin-walled or soft pipes, use a reinforcement sleeve.

2) Lubricate the support thread and cone, union nut inside and cutting ring well with oil. Always use PASTE ES for stainless steel cutting ring couplings (optional for NC couplings).

3) Slide union nut and cutting ring onto tube. Observe the correct position of the cutting ring/NC clamping ring - otherwise it will be mounted incorrectly.

4) Tighten the union nut by hand as far as possible. Mark the union nut to check the specified rotations. Press the tube into the cone as far as it will go. Tighten the union nut with a wrench for approx. 1 revolution. Tube should not rotate.

5) To check the installation, loosen the union nut. Cutting ring: The ejected tube material should cover the front cutting ring face. If not, tighten a little more. Due to the spring action of the cutting ring, it can still rotate – this is not an error. NC clamping ring: The clamping ring must not move any more.

6) Final assembly: Install union nut on supports until there is a noticeable increase in strength. Then tighten by 1/4 - 1/2 revolution (cutting ring coupling) or 3/4 revolution (NC clamping ring coupling).

Please note:

Installation of stainless steel couplings only using suitable lubricants.

Notes on NC Clamp Ring Couplings

Advantages:

•Compatible with any cutting ring coupling in accordance with DIN EN ISO 8434-1 (DIN 2353). •Can also withstand dynamic loads such as vibrations and pulsations. •Can be unscrewed and retightened as many times as desired. •Unlike a cutting ring, NC clamping ring is not hardened, so it cannot rust and has good chemical resistance. •Lubrication of the threads of the nut is not necessary during initial assembly due to a silver coating., •Vacuum density Q< 10^8 mbar l/s, •Ideal for use in the gas and water industry

Required pipe quality:

The couplings must be machined with heat-treated, seamless stainless steel pipes (1.4571) in accordance with DIN EN ISO 1127. The tolerance class must be D4/T3, the surface must not be damaged and the hardness must not exceed Rockwel HRB 90.

*Nuts and cutting ring are supplied separately

Type galvanized steel

Materials

Body: Galvanized steel or available elastomer seal: NBR

Temperature range:

-40 °C to max. +120 °C (with elastomer seal: -35 °C to max. +100 °C)

Stainless Steel Type & NC Coupling

Materials

Body: 1.4571, any available elastomer seal: FKM

Temperature range:

-60 °C to max. +400 °C (with elastomer seal: -20 °C up to max. +200 °C, NC couplings up to +550 °C on request)

Mounting Cutting Ring Couplings and NC Clamping Ring Couplings

1) Cut the pipe in a rectangular way and deburr and clean the inside and outside. Do not use a tube cutter. For thin-walled or soft pipes, use a reinforcement sleeve.

2) Lubricate the support thread and cone, union nut inside and cutting ring well with oil. Always use PASTE ES for stainless steel cutting ring couplings (optional for NC couplings).

3) Slide union nut and cutting ring onto tube. Observe the correct position of the cutting ring/NC clamping ring - otherwise it will be mounted incorrectly.

4) Tighten the union nut by hand as far as possible. Mark the union nut to check the specified rotations. Press the tube into the cone as far as it will go. Tighten the union nut with a wrench for approx. 1 revolution. Tube should not rotate.

5) To check the installation, loosen the union nut. Cutting ring: The ejected tube material should cover the front cutting ring face. If not, tighten a little more. Due to the spring action of the cutting ring, it can still rotate – this is not an error. NC clamping ring: The clamping ring must not move any more.

6) Final assembly: Install union nut on supports until there is a noticeable increase in strength. Then tighten by 1/4 - 1/2 revolution (cutting ring coupling) or 3/4 revolution (NC clamping ring coupling).

Please note:

Installation of stainless steel couplings only using suitable lubricants.

Notes on NC Clamp Ring Couplings

Advantages:

•Compatible with any cutting ring coupling in accordance with DIN EN ISO 8434-1 (DIN 2353). •Can also withstand dynamic loads such as vibrations and pulsations. •Can be unscrewed and retightened as many times as desired. •Unlike a cutting ring, NC clamping ring is not hardened, so it cannot rust and has good chemical resistance. •Lubrication of the thread of the nut is not necessary during the initial assembly due to a silver coating., •Vacuum density Q< 10^8 mbar l/s, •Ideal for use in the gas and water industry

Required pipe quality:

The couplings must be machined with heat-treated, seamless stainless steel pipes (1.4571) in accordance with DIN EN ISO 1127. The tolerance class must be D4/T3, the surface must not be damaged and the hardness must not exceed Rockwel HRB 90.

*Nuts and cutting ring are supplied separately