In the world of hydraulic systems, reliable connections are indispensable. The ORFS fittings play a key role in this.

ORFS fittings stand for O-Ring Face Seal. These fittings are known for its 100% leak-proof connection (when fitted correctly), robust specifications and wide range of applications.

In this article, we will dive further into the technical basics of ORFS fittings. This gives you an overview of why these components are suitable for modern, reliable hydraulic applications.

What are ORFS fittings?

ORFS (O-Ring Face Seal) fittings are hydraulic connections that seal via a flat metal connection in combination with an O-ring. They are used in systems where high pressure, vibration and leak-free operation are crucial. The fittings comply with the following standards:

Technical Operation of ORFS Fittings

The O-ring and sealing surface

An ORFS fitting has:

-

A flat metal sealing surface (face)

-

An elastic O-ring (usually NBR, Viton, or EPDM)

-

A straight UN/UNF thread that only provides the mechanical connection, not the seal

When mounted, the O-ring is pressed against the plane in an axial direction. This results in a stable, vibration-resistant and completely leak-free seal.

Threading and mounting

The thread does not provide sealing, but a solid mechanical connection. Each nominal size has a specific UNF thread and TPI (Threads per Inch). Correct assembly is essential for optimal performance.

Advantages of ORFS Fittings

-

No metal-to-metal seal wear

-

Compensates for slight misalignment

-

Good resistance to vibration

-

Very suitable for high pressure (up to ± 630 bar, depending on size)

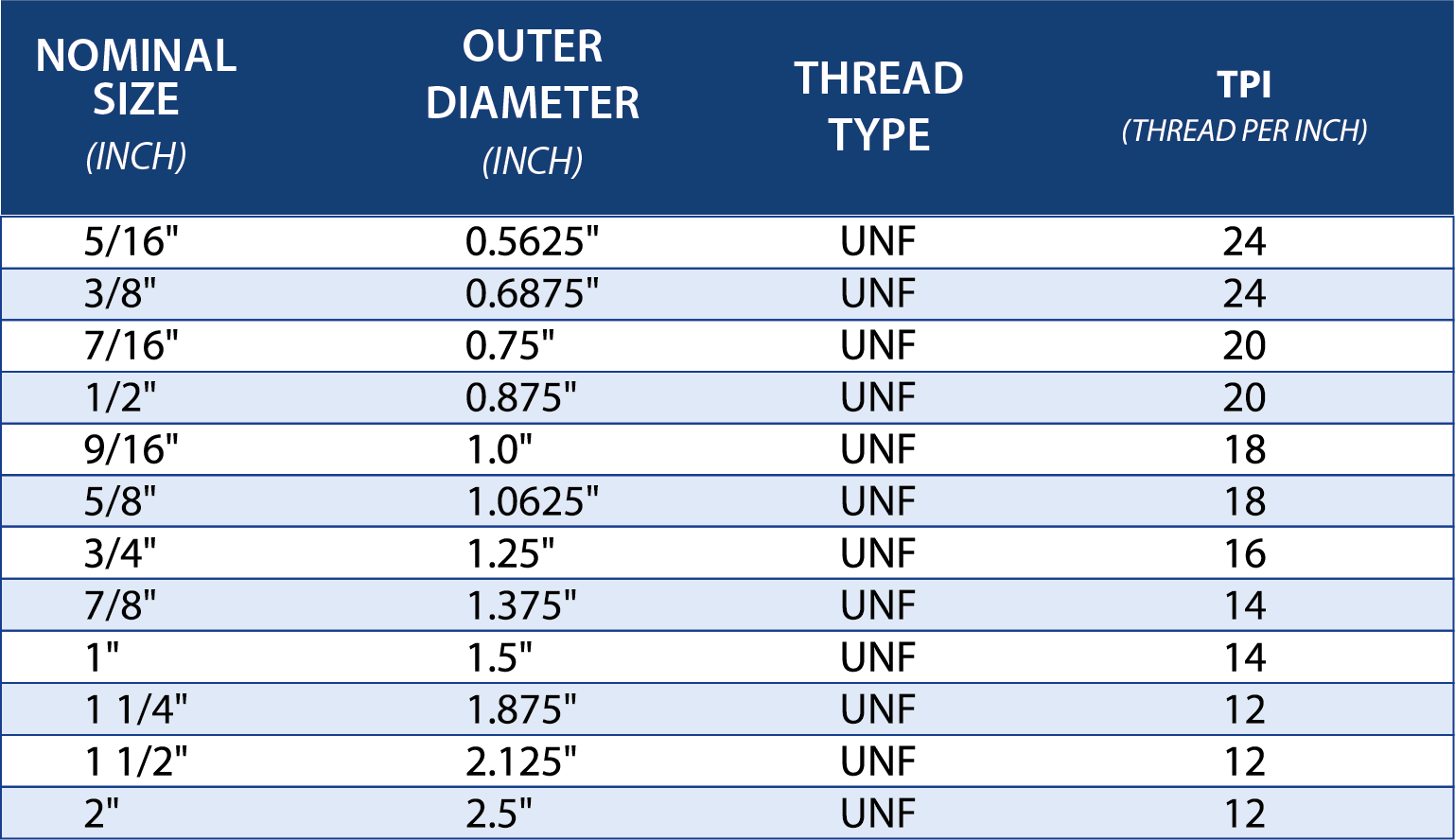

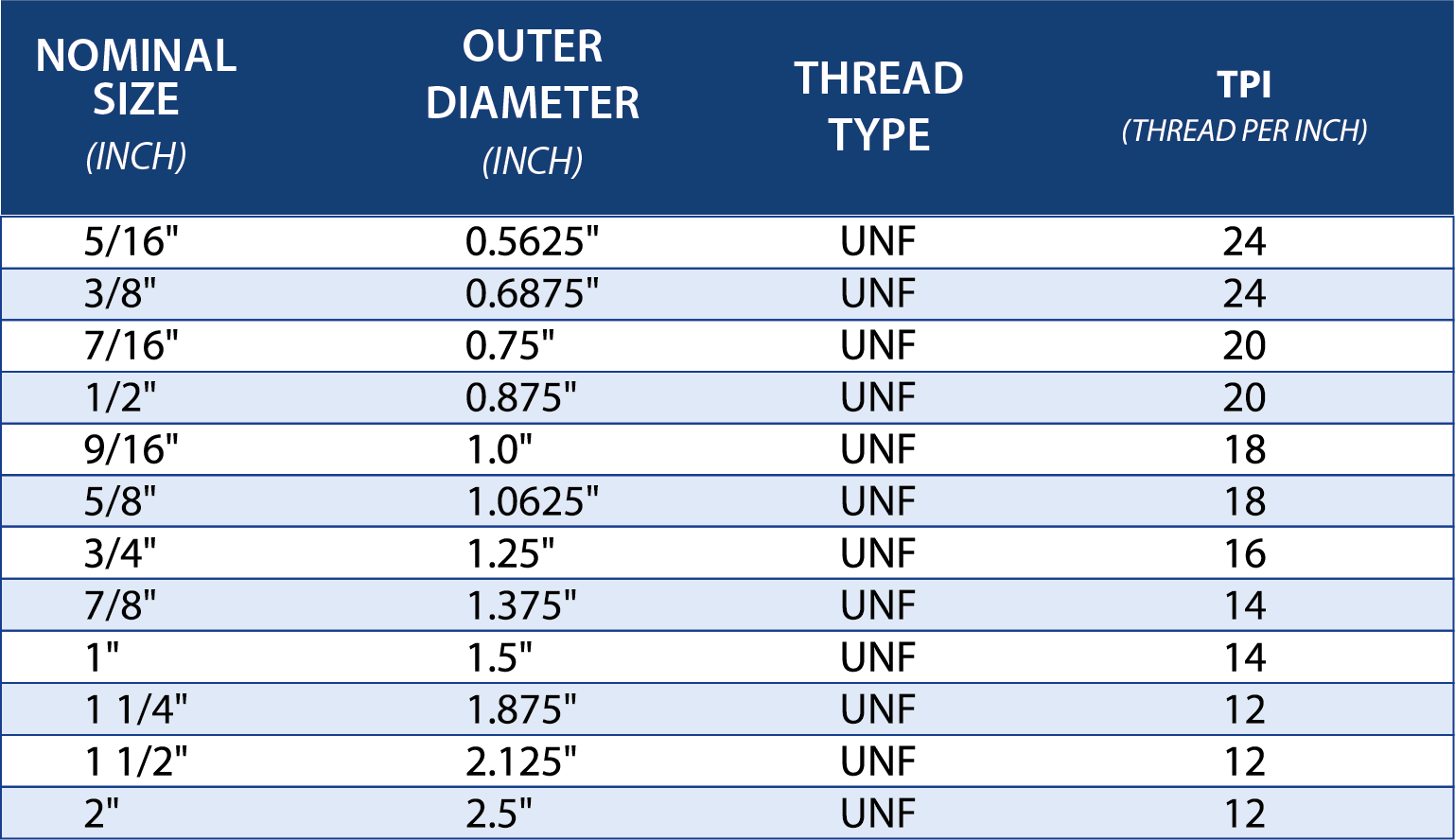

Nominal sizes and threads

Each ORFS fitting has a specific thread that belongs to that size.

Below is an overview of the most commonly used ORFS fittings:

Explanation:

-

Nominal size: the "inch fraction" of the pipe/fitting

-

Outer diameter: diameter of the thread (not of the O-ring).

-

Thread type: standard UNF (Unified Fine Thread), usually used for ORFS

-

TPI: the number of threaded teeth per inch, important for fit.

ORFS is less about the diameter of the O-ring and more about the right thread and nominal size. The O-ring is in the "face" and provides the seal.

Easily find the right thread size

Discover ORFS fittings for hydraulic systems. 100% leak-proof connections, suitable for high pressure and vibrations. View our range here.

If you have any questions or need advice on choosing your ORFS fitting, please feel free to contact us and we will be ready to help you.

Back to knowledge pages