At Pneuparts, in Deurne, Noord-Brabant, we see every day how essential the performance of your machines is to the success of your business. Our mission is simple: to support you in achieving maximum efficiency and the longest lifespan from your equipment.

It often starts with something you might take for granted, but which makes a world of difference: air quality ISO 8573-1. Without the right approach, contaminated compressed air can lead to costly downtime and even product spoilage.

We believe in a personal approach, sharing our extensive knowledge of pneumatics in a clear and practical way. In this article, we dive deep into the world of compressed air quality according to ISO 8573-1, the international standard that sets the benchmark for clean compressed air systems.

Why Compressed Air Quality According to ISO 8573-1 Is Crucial for Your Success

Compressed air is an essential energy source in almost every industry, from food and pharmaceuticals to heavy manufacturing. However, the air coming from a compressor is far from as clean as you might think. It naturally contains various contaminants: solid particles (such as dust), moisture (as vapor or liquid water), and oil (as aerosols or vapors).

When these contaminants reach sensitive equipment, they can cause serious malfunctions, lead to corrosion, and directly affect the quality of your final products.

This is where the ISO 8573 standard comes in. This international standard provides a standardized method for defining the purity level of compressed air. The most commonly used and important specification within this standard is ISO 8573-1.

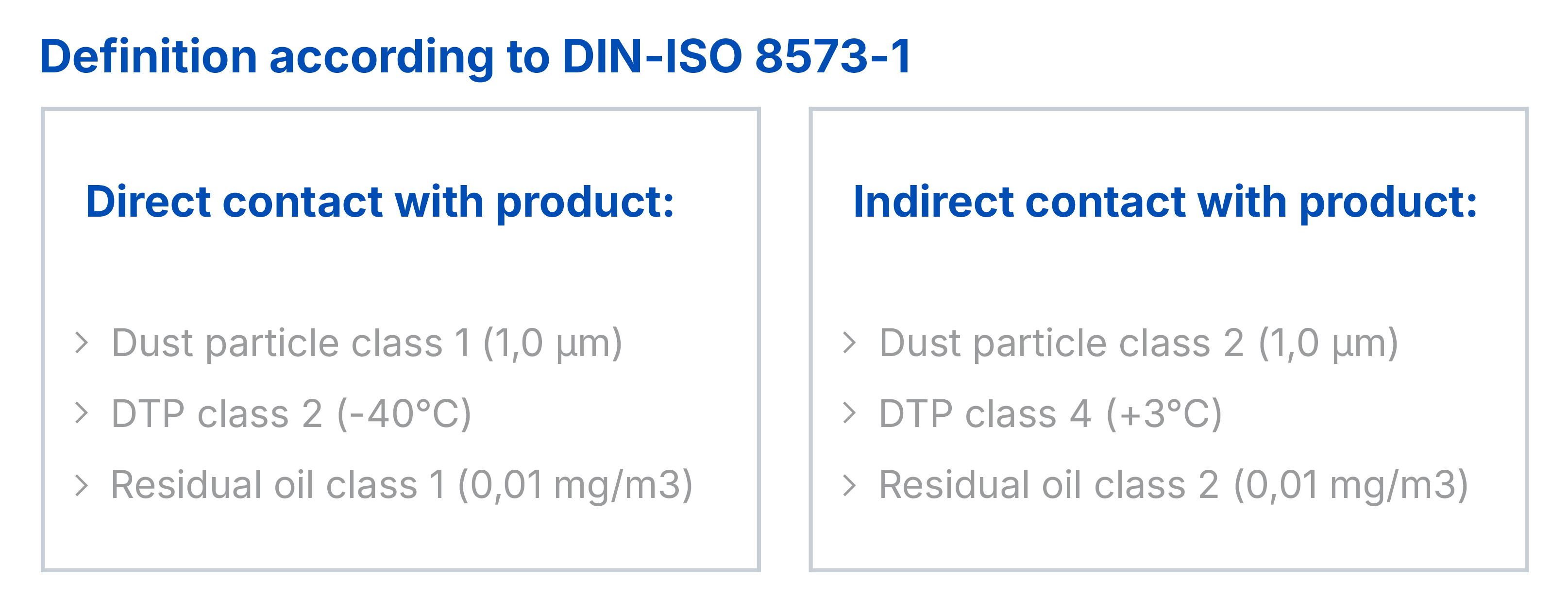

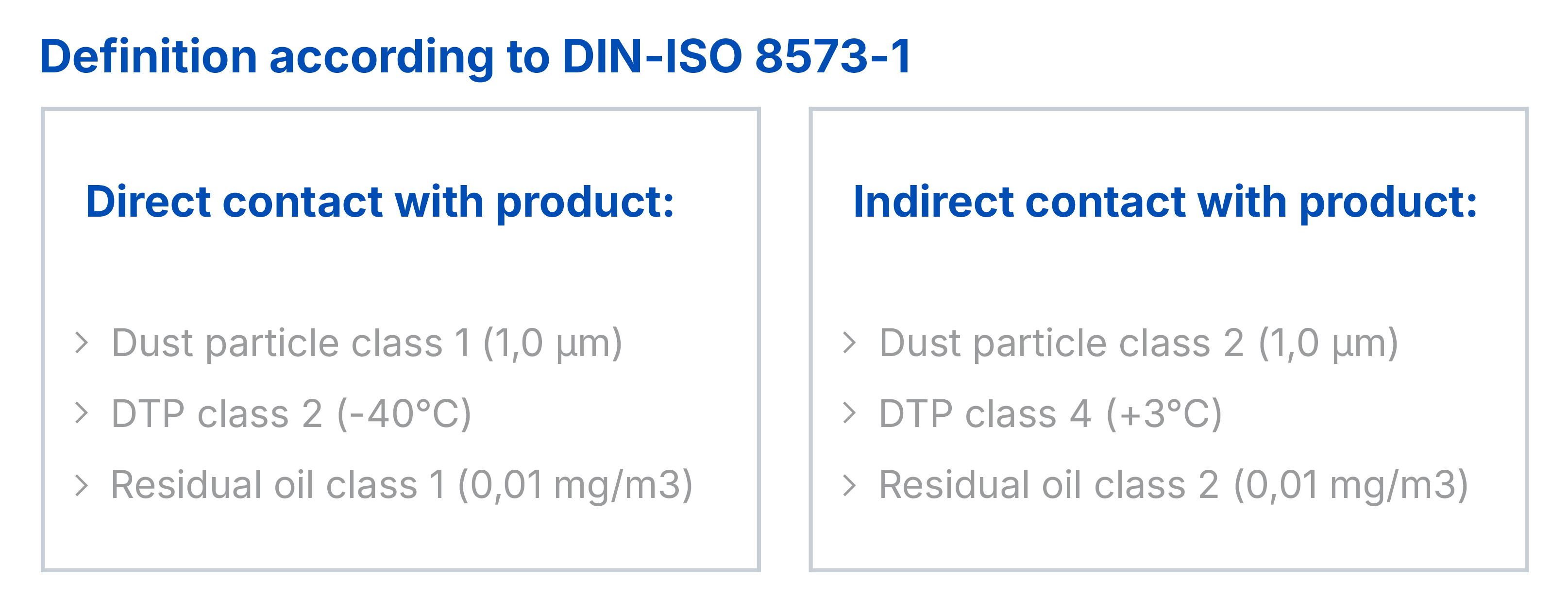

Below you can see how air quality is divided into three categories, or quality classes, each relating to a specific type of contaminant:

| |

Contaminant

|

Class 1

|

Class 3

|

Class 5

|

| |

Solid Particles (max particle size in μm)

|

Max. 0,1

|

Max. 5,0

|

Max. 40

|

| |

Dew Point (°C)

|

−70

|

−20

|

+7

|

| |

Total Oil Content (mg/m³)

|

Max. 0,01

|

Max. 1,0

|

Max. 25

|

The first class represents solid particles, the second represents dew point/moisture, and the third represents oil. It is the key to ensuring the reliability of your equipment and the quality of your products.

Choosing the Right Filters: Essential for Your Required Air Quality

Achieving the desired compressed air quality according to ISO 8573 is not a matter of luck, but of properly treating the compressed air using the appropriate filters and dryers. The choice of your filters and dryers is directly linked to the sensitivity of your production process and end products.

To remove solid particles and liquid water/oil, start with a pre-filter, followed by a fine filter. If you want to achieve extremely high purity, for example in critical applications in the food or medical industry, you may need a submicron filter and an activated carbon filter to further reduce oil vapors and hydrocarbons.

| |

For the class concerning solid particles, one should consider the maximum particle size still allowed.

A filter with a small pore size ensures a lower number of remaining particles. If your specific application has an extremely low tolerance for oil, consider using oil-free compressors combined with activated carbon filters, which minimize the chance of oil contamination.

The standard for oil content is crucial, especially in the food and packaging industries where food safety is of utmost importance.

|

| |

Moisture and Dew Point Control

The second class in the ISO 8573-1 coding focuses on the dew point, which is a measure of the moisture content in the air.

The lower the dew point, the drier the compressed air. In many applications, dry compressed air is required to protect against corrosion and equipment damage. Dryers (such as refrigerated or adsorption dryers) are indispensable in the compressed air system.

An adsorption dryer achieves a much lower dew point than a refrigerated dryer and is often required in critical applications or outdoor transport at low temperatures. The presence of water vapor must be mapped, and the appropriate moisture treatment system must be selected to meet the limit of the chosen class.

|

The ISO 8573-1 Table in Practice

To determine which quality classes are required, look at the most sensitive component in your production process or the end product being produced.

The table above shows a simplified overview of the ISO 8573-1 classes for better understanding. Through this class coding, for example class 1.4.1, you know exactly what requirements your specific application demands.

For the production of pharmaceutical products or in the chip industry, you will typically aim for class 1.1.1, the highest purity. For less critical applications, such as general transport in a workshop, class 5.4.4 may suffice.

It is your responsibility to determine these requirements, and Pneuparts is happy to assist you in selecting the right equipment and filters to meet this standard.

Correct measurement and monitoring of compressed air quality are carried out using specific test methods and sensors to measure, for example, dew point or oil content. This ensures confidence in the consistency of your production process. Optimizing your compressed air systems is an ongoing process.

Air Quality ISO 8573-1 Ensures Continuity

A solid understanding of air quality ISO 8573-1 is essential for any business owner who wants to keep machines performing optimally and prevent costly breakdowns. The ISO 8573 standard plays a key role in defining the purity of compressed air in terms of solid particles, moisture, and oil.

Achieving the correct class depends on selecting and maintaining the right filters, dryers, and using the appropriate testing methods for your specific application.

Do you have questions or would you like to request a quote?

At Pneuparts in Deurne, we’re ready to assist you with our expertise and products to ensure compressed air quality according to ISO 8573-1 in your system. Want a personalized quote? We offer tailored advice and the right filters to optimize your compressed air system and get the most out of your production.

Want to know more?

Would you like to know which quality classes your critical applications really require and how to achieve them in the most sustainable way? Contact the experts at Pneuparts today for tailored advice and confidence in your compressed air quality.

Frequently Asked Questions (FAQ)

What does ISO 8573-1 mean and why is this standard important for compressed air quality?

ISO 8573-1 is the international standard that defines the purity of compressed air. The standard classifies compressed air based on three types of contaminants: solid particles, moisture (dew point), and oil. For companies in industries such as food processing, pharmaceuticals, and manufacturing, this standard is crucial to ensure product quality, protect machinery, and prevent downtime. By working according to ISO 8573-1, you know exactly which air quality your application requires.

Which ISO 8573-1 class do I need for my application?

The correct ISO 8573-1 class depends on the most critical component or the final product within your process. For highly sensitive applications, such as pharmaceutical production or cleanrooms, class 1.1.1 is often required. For less critical applications, such as general pneumatic tools in a workshop, class 5.4.4 may be sufficient. A specialist such as FHT Perslucht can help determine the correct class and the appropriate filters and dryers.

How can I purify compressed air according to ISO 8573-1 and continue to monitor it?

Achieving the required compressed air quality according to ISO 8573-1 requires a combination of compressors, filters, and dryers, such as pre-filters, fine filters, activated carbon filters, and refrigerated or adsorption dryers. In addition, it is important to regularly measure and monitor air quality, for example by checking the dew point and oil content using sensors and test methods. This ensures your compressed air system remains reliable and compliant with the standard.

Back to knowledge pages